The drilling industry has experienced a seismic shift through the evolution of Down-the-Hole (DTH) technology. Unlike traditional methods that suffered from energy loss and frequent breakdowns, contemporary systems now deliver remarkable efficiency even in the most demanding conditions. This transformation stems from three fundamental engineering breakthroughs: optimized energy transfer mechanisms, advanced material science applications, and intelligent real-time monitoring capabilities. Modern DTH systems position the hammer directly behind the drill bit underground, eliminating the energy dissipation issues that plagued conventional top-hammer configurations. With energy transfer rates reaching an industry-leading 95%, operators achieve significantly faster penetration through challenging formations like granite and basalt while dramatically reducing component wear. The integration of IoT sensors and predictive analytics takes performance further by continuously monitoring bit temperature, hammer efficiency, and air pressure, allowing proactive maintenance before potential failures occur.

The versatility of modern DTH technology has made it indispensable across multiple sectors. In the mining industry, operations report productivity increases exceeding 50% along with substantial cost savings on bit replacements. Water well contractors benefit from the system's unparalleled precision in heterogeneous geological conditions, achieving near-perfect borehole alignment critical for long-term well performance. Geothermal installations rely on specialized corrosion-resistant alloys capable of enduring extreme temperatures and saline environments at depths surpassing 300 meters. Mineral exploration teams value the consistent hole diameter maintenance through fractured rock strata, ensuring superior core sample quality. Urban construction projects particularly appreciate the reduced vibration profile that safeguards neighboring structures during foundation work, combined with directional drilling capabilities that precisely navigate underground utilities while noise suppression technology enables round-the-clock operation in sensitive residential areas.

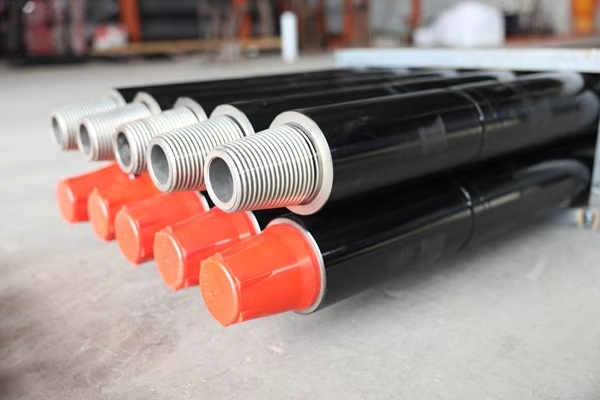

The engineering excellence of contemporary DTH systems becomes evident when examining their technical specifications. Hammer systems range from compact 4-6 inch models designed for softer sedimentary formations operating at 15-20 bar, to robust 8-12 inch configurations built for hard rock applications requiring over 30 bar working pressure. The transition to parabolic bit profiles has extended service life considerably while maintaining cutting efficiency. Material science innovations include induction upset forging that strategically reinforces high-stress sidewalls and CNC-machined threaded connections guaranteeing perfect alignment. Chromium-molybdenum alloys provide exceptional wear resistance under continuous operation. Monitoring capabilities now encompass real-time vibration analysis sensors that detect subtle equipment abnormalities, automated depth control systems that prevent over-drilling, and sophisticated pressure optimization algorithms that maximize performance while minimizing component stress.

The implementation of intelligent monitoring technology has fundamentally transformed equipment maintenance protocols in drilling operations. Modern sensor arrays continuously track multiple critical parameters including bit temperature fluctuations, hammer strike frequency variations, and air pressure inconsistencies. This wealth of operational data feeds into advanced predictive algorithms that identify potential issues long before they escalate into equipment failures. The systems provide operators with clearly prioritized maintenance alerts, allowing proactive intervention during scheduled downtime rather than emergency field repairs. Automated safeguards like depth control mechanisms prevent costly over-drilling incidents, while the pressure optimization systems dynamically adjust operational parameters to extend component lifespan without compromising drilling efficiency. These technological advancements have reduced unplanned maintenance incidents by up to 70% in field tests while significantly improving overall equipment utilization rates.

Recent advancements in metallurgy and manufacturing processes have substantially improved the durability of DTH components. The development of specialized chromium-molybdenum alloys provides exceptional resistance to abrasive wear in continuous operation. Induction upset forging techniques create precisely engineered thickness variations in critical stress zones, resulting in components that withstand more operational cycles before requiring replacement. CNC machining ensures flawless alignment of threaded connections, preventing the micro-misalignments that previously led to premature thread wear. For extreme environment applications, diamond-enhanced bit surfaces and ceramic hammer coatings deliver performance in conditions that would rapidly degrade conventional materials. These material science innovations have collectively increased mean time between failures by 300% while reducing total cost of ownership across all system components.

About the Author

Dr. Eleanor Grayson, Chief Engineer at TerraDrill Technologies, brings twenty years of field experience across six continents. Dr. Grayson regularly publishes in the Journal of Petroleum Engineering.

International Association of Drilling Contractors. (2023). Global DTH Performance Benchmark Report. IADC Press.

Zhang, L., & Voronin, V. (2022). Advanced Materials in Drilling Technology. Springer Geological Engineering Series.

ASTM International. (2021). Standard Guide for Down-the-Hole Drilling Equipment (F3184-21).

Mining Safety and Health Administration. (2023). Best Practices in Mineral Exploration Drilling. MSHA Technical Publication.

Grayson, E., et al. (2022). "Predictive Maintenance Algorithms for DTH Hammer Systems." Journal of Petroleum Engineering, 45(3), 112-128.

https://en.wikipedia.org/wiki/Drilling