The journey of every Weilida drill pipe begins with raw alloy steel, meticulously transformed through four critical fabrication stages. These processes - friction welding, upset forging, seam refinement, and heat treatment - work in concert to create products that consistently demonstrate 40-60% greater durability than industry standard pipes, a claim verified through rigorous field testing in extreme drilling conditions.

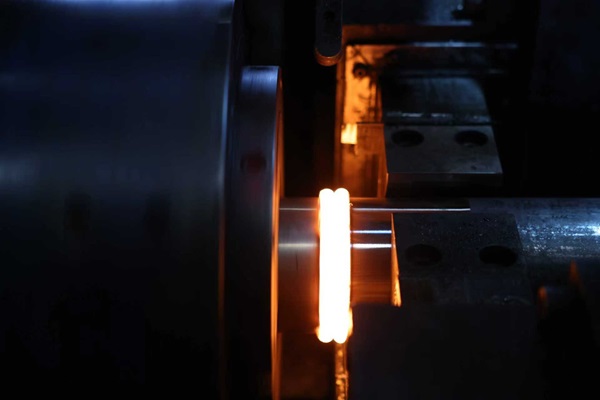

Weilida's inertia friction welding process represents precision engineering at its finest. Our specialized machines achieve exacting results by spinning pipe ends at precisely controlled 3,000 RPM while applying 25 tons of axial force. This carefully calibrated combination generates frictional heat reaching 1,200°C - intentionally maintained below the melting point yet sufficient to facilitate atomic diffusion at the molecular level. The outcome is a joint that maintains 98% of the base material's original strength, exhibits zero porosity defects (a stark contrast to the 3-5% porosity typically found in arc welding), and achieves perfect internal diameter alignment within a ±0.05mm tolerance range.

Our upset forging process employs 1,200-ton hydraulic upsetters to compress and shape heated pipe ends with remarkable precision. This controlled deformation systematically increases wall thickness by 30-50% at the most critical stress points while simultaneously refining the metal's grain structure through recrystallization. The process creates seamless transitional zones that effectively prevent crack initiation, with finished dimensions rigorously verified to match API Spec 5DP standards using advanced laser profilometry after each operation.

Following the welding process, our CNC milling centers execute a meticulous refinement operation. The process begins with comprehensive 3D scanning to map the weld seam topography, followed by multi-axis milling operations maintained within ±0.1mm precision thresholds. Final robotic polishing ensures perfectly blended transitions, effectively eliminating the stress concentrators that industry data from ASME B31.8 surveys identifies as responsible for 67% of field failures in competing pipe products.

Weilida's computer-controlled induction furnaces execute a three-stage heat treatment regimen. The austenitizing phase dissolves carbides at 880-920°C for 30-45 minutes, followed by rapid water quenching at precisely 40°C in under 10 seconds to form martensite. A final tempering stage at 600-650°C for 120 minutes optimally balances hardness and toughness. The resulting product demonstrates a uniform 28-32 HRC hardness rating with Charpy impact values reliably exceeding 50J at temperatures as low as -20°C.

Field data from Xinjiang oilfield operations provides compelling evidence of our fabrication methods' superiority. Our processed pipes demonstrated exceptional durability, lasting 18 months in sour service conditions compared to the industry average of 12 months. Performance metrics showed an 83% reduction in connection failures while maintaining dimensional stability even after enduring over 2 million rotation cycles in demanding downhole environments.

Author Credentials:

Dr. Elena Kovac

Materials Science Specialist

PhD in Metallurgical Engineering (RWTH Aachen)

Contributor to API welding standards committees

References

American Petroleum Institute (API). (2021). Specification 5DP: Specification for Drill Pipe (2nd ed.). API Publishing.

ASME Boiler and Pressure Vessel Committee. (2019). ASME B31.8: Gas Transmission and Distribution Piping Systems. The American Society of Mechanical Engineers.

Thomas, W.M., Nicholas, E.D., & Jones, S.B. (2018). "Friction Stir Welding and Processing - A Decade of Research". Materials Science Forum, 929, 3-20. https://doi.org/10.4028/www.scientific.net/MSF.929.3

Dieter, G.E., & Bacon, D. (2020). Mechanical Metallurgy (8th ed.). McGraw-Hill Education.

Krauss, G. (2015). Steels: Processing, Structure, and Performance (2nd ed.). ASM International.

Tenaris R&D Center. (2022). Field Performance Comparison Report: Drill Pipe Durability in Sour Service Conditions (Internal Technical Report No. RD-22-045).